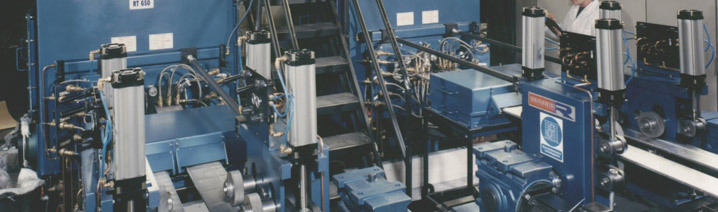

Specification:

- Orientation: Horizontal

- Strip width: up to 360mm

- Rod diameter: up to 175mm

- Tube OD: up to 150mm

- 2 strands bar/hollow up to 150mm dia., or

- 4 strands rod up to 15mm dia.

- Graphite crucible 59 or 70 litres

- 150 kVA power rating

- 1350 deg.C maximum furnace temperature

- 300 kg/hr (ingot feed - fine silver)

- 600 kg/hr (liquid feed - fine silver and silver alloy)

The RT 650 machine may be used either as an integrated melting & casting furnace or as a casting furnace with separate primary melting & alloying furnace to increase output capacity to 600 kg/hr.

Withdrawal options:

- 1289; 5798; 10794; 11098; 13179

Withdrawal drive options:

- AC positional servo or AC

Options:

- primary melting equipment; plant monitoring; rod coiling; billet/bar cutting & handling; strip cutting & coiling; operator platform

Rautomead technology provides the capability to produce top quality continuous cast alloy shapes by offering accurate control and repeatability of production parameters.

The graphite crucible provides a naturally reducing environment in which to contain the liquid metal. It is conducive to the production of metallurgically clean, oxygen-free cast product without inclusions, voids or other defects.

The electric resistance graphite heating system operates at a safe, low voltage and is simple to operate and maintain.

RT 650 model continuous casting machines are manufactured to order. Specification of withdrawal unit, controls and tooling are selected to suit each particular customer's requirements.

Machines are installed and tested at the Rautomead factory before packing and dispatch. Rautomead engineers are available to supervise installation, start-up, commissioning and training of customer's engineers.